Aluminum Heat Treatment

Aluminum Heat Treatment - involves solutionising and precipitation treatment to give the job desired strength and hardness properties.

Range

Various Grades of Aluminium which are heat treatable.

How it works

Here are some heat treatment processes for aluminium:

- Solution heat treatment

Involves heating the aluminum to a temperature above its solvus temperature, then rapidly cooling it in a liquid. This process improves the mechanical properties of the aluminum, such as its strength.

- Quenching

Involves rapidly cooling a heated metal in a colder liquid, such as oil, water, or air. This process increases the alloy's strength and corrosion resistance.

- Precipitation hardening

Also known as artificial aging, this process is used to bring some aluminum alloys to their maximum hardness. It involves heating the alloy to a specific temperature between 240°F and 460°F, then air cooling it to room temperature.

- Tempering

Usually follows the hardening process to remove brittleness while retaining the alloy's hardness.

Other heat treatment processes for aluminum include annealing and homogenizing

Benefits

- Increased Strength.

- Enhanced Formability

- Improved Resistance to Corrosion.

Typical material used

Aluminium is a material that can be used in a variety of heat treatment processes, including annealing, solution heat treatment, quenching, and tempering

Applications

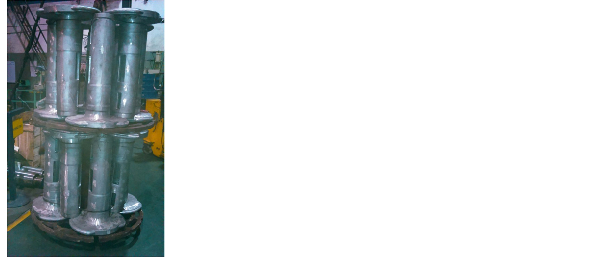

Transmission Castings.

Fan Casings