Nitriding

Nitriding provides high wear resisitance besides corrosion resisitance by diffusing nitrogen into the steel surface to form nitrides with iron and alloying elements.Case depths are shallow and Post heat treatment distortions are minimal.

Nitriding is a heat treatment process that improves the surface hardness and wear resistance of steel

and other materials

Nitriding is an effective surface hardening process that enhances the mechanical

properties of steel

components, making them more durable and wear-resistant. Its applications span various industries,

particularly in environments where reliability and longevity are crucial.

How It Works

Preparation: The material, typically steel, is cleaned to ensure no contaminants interfere with the

process.

Heating: The component is heated to a temperature typically between 900°F and 1200°F (480°C to

650°C) in an ammonia (NH₃) atmosphere or other nitrogen-rich environments.

Diffusion: Nitrogen from the ammonia diffuses into the surface of the steel, forming hard nitrides

(e.g.,

iron nitrides). This diffusion occurs over several hours, depending on the desired depth of hardening.

Cooling: The part is then cooled, which can be done in air or other controlled environments.

Benefits

Increased Surface Hardness: Nitriding significantly enhances surface hardness, often achieving

hardness

values of 60 HRC or higher.

Improved Wear Resistance: The hardened surface provides excellent resistance to wear, making it

suitable for demanding applications.

Enhanced Fatigue Strength: Nitriding improves the fatigue life of components, making them more

reliable under cyclic loads.

Reduced Distortion: The process is performed at lower temperatures compared to other hardening

methods, resulting in minimal distortion of the component.

Corrosion Resistance: Nitrided surfaces can exhibit improved corrosion resistance due to the formation

of a hard, protective layer.

Typical Materials Used

Alloy Steels: Commonly used for parts like gears, shafts, and other critical components.

Carbon Steels: Suitable for a variety of applications needing improved surface properties.

Certain Tool Steels: Tool steels can also benefit from nitriding to enhance their performance in

cutting

and forming applications.

Customers Reviews

John Doe

Diam amet duo labore stet elitr invidunt ea clita ipsum voluptua, tempor labore accusam ipsum et no at. Kasd diam tempor rebum magna dolores sed eirmod

Kerald Bob

Diam amet duo labore stet elitr invidunt ea clita ipsum voluptua, tempor labore accusam ipsum et no at. Kasd diam tempor rebum magna dolores sed eirmod

Applications

Automotive Components

Gears, camshafts, and crankshafts that require high wear resistance.

Aerospace

Components like landing gear and turbine blades that must withstand high stresses.

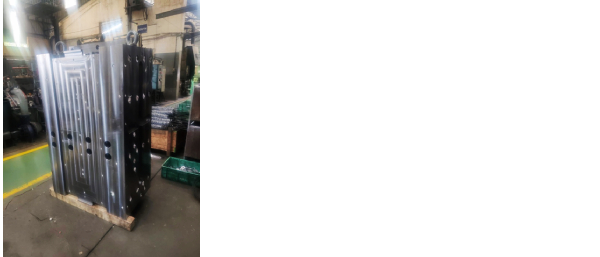

Industrial Machinery

Parts such as bearings, molds, and dies used in manufacturing processes.

Tooling

Cutting tools and dies that experience significant wear.